CNC Machining Solutions for the Oil & Gas Industry

The Oil & Gas industry demands components that operate under extreme conditions—high

pressure, temperature, and corrosion. LMW offers advanced CNC machining solutions

specifically designed to meet these challenges, ensuring superior performance, reliability, and

efficiency.

Application Solutions for the Oil and Gas Industry

Application solutions for Oil & Gas Industry

The oil and gas industry demands engineering excellence across upstream, midstream, and downstream operations. From the harsh environments of offshore drilling to the high-precision demands of refining, component reliability and machining accuracy are critical. Our comprehensive machining solutions cater to the full spectrum of applications in this sector—supporting the manufacture of drilling tools, pipeline fittings, valve assemblies, and refinery equipment with exceptional precision, efficiency, and repeatability.

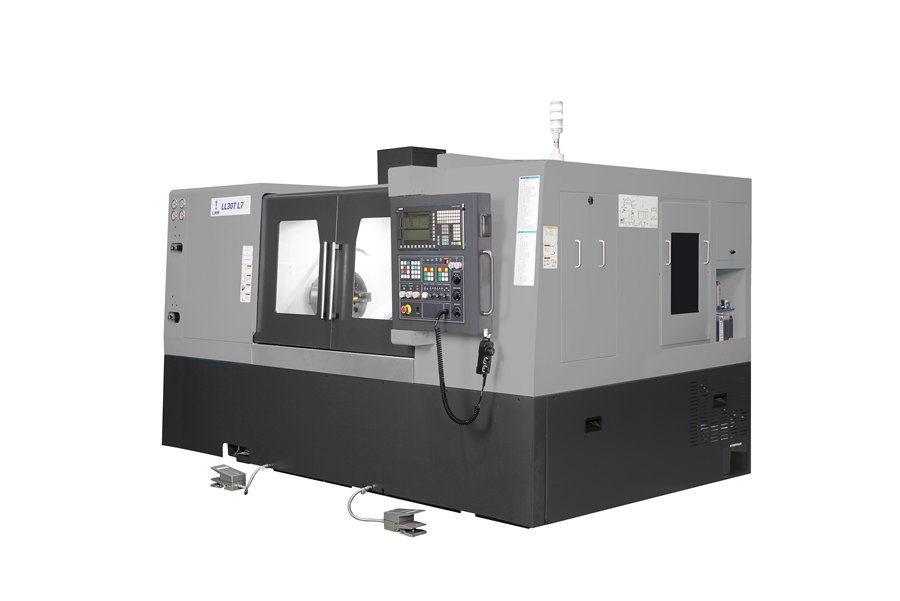

Drilling Components

In drilling operations, components such as drill collars, stabilizers, mud motors, casing heads, and BOP housings must endure extreme pressure, torque, and wear. Our robust CNC turning centers and machining solutions are engineered to handle tough materials like Inconel and stainless steel, ensuring tight tolerances, high concentricity, and superior surface finishes.

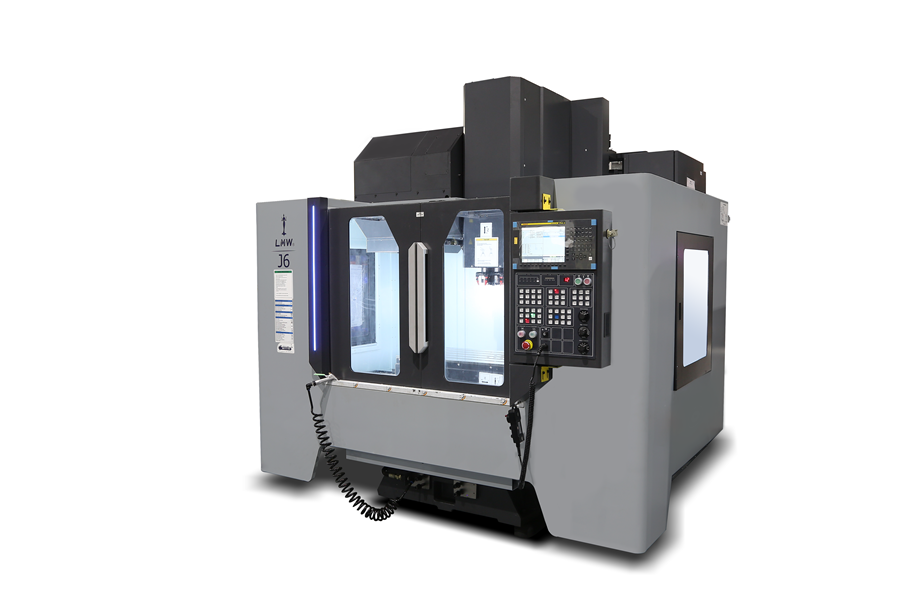

Flow Control Systems

Flow control systems, which play a vital role in regulating fluids throughout oilfield and processing infrastructure, also benefit greatly from our precision machining technology. Gate, globe, ball, and check valves—as well as actuator housings, spindles, and sealing elements—require highly accurate machining to ensure leak-proof performance and durability under high pressure. Our turnmill centers and VMCs offer high-speed operations, automated tool changes, and contouring abilities that simplify complex part production and reduce lead times.

Pipeline Systems

Pipeline systems form the core of midstream oil and gas transport and require a wide range of machined components including flanges, elbows, couplings, clamps, and pig launcher/receiver bodies. These parts must meet strict standards for corrosion resistance and dimensional accuracy. Our large-capacity machines and flexible fixturing systems are ideal for producing both standard and customized pipeline components with high repeatability and minimal downtime.

Refinery Equipment

In downstream refining, equipment is exposed to elevated temperatures, chemical corrosion, and continuous usage. We support the production of refinery-critical components such as heat exchanger tube sheets, baffle plates, burner housings, impellers, pressure vessel flanges, and pump casings. Our horizontal and vertical machining centers are designed for heavy-duty performance and enable seamless handling of large, complex parts required in refinery environments.

Other Precision Parts

Beyond these key segments, we also serve extended oil and gas applications such as compressor systems, offshore platform components, manifold blocks, turbine parts, and structural elements for rigs and FPSOs. Our solutions can be scaled from standalone machining setups to fully integrated, automated production lines equipped with robotic part handling and in-process quality monitoring systems.

How LMW Supports the Oil & Gas Industry

LMW CNC provides heavy-duty, reliable machining solutions designed to meet the demands of the oil and gas industry. Our machines are built for machining tough materials and large components with high accuracy and consistency—ideal for producing parts like valve bodies, flanges, drill tools, and heat exchanger components. With a strong focus on durability, precision, and service support, LMW helps manufacturers in the oil and gas sector maintain quality and efficiency in every operation.

Oil & Gas Components

Conventional Seal

Flanged Ball Valve

Hydraulic Swivel Joint

Pipe

Rotary Union

Transfer Case Input Shaft