Horizontal Machining Centers (HMCs): Precision, Power & Productivity

The manufacturing sector is evolving rapidly — driven by the need for precision, shorter lead times, and increased output. At the heart of this transformation is the Horizontal Machining Center (HMC) — a powerful solution that’s redefining how industries approach complex machining tasks.

What is a Horizontal Machining Center?

A Horizontal Machining Center is a CNC machine with a horizontal spindle orientation, allowing parts to be machined from multiple sides in fewer setups. Unlike vertical machines, HMCs offer gravity-aided chip evacuation, improved surface finish, and better productivity — making them ideal for high-precision, high-volume applications.

Horizontal Machining Centers

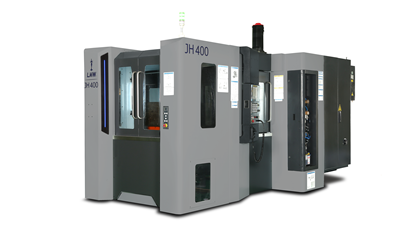

JH 400

The JH 400 Heavy Duty Horizontal Machining Center is designed for demanding applications, offering a stroke of 600 mm x 600 mm x 640 mm, a pallet size of 400 mm x 500 mm.

JHF 400

The JHF 400 High-Speed Horizontal Machining Center combines speed and precision with a stroke of 600 mm x 500 mm x 500 mm, an automatic pallet changer with a size of 400 mm x 400 mm.

Applications

Automobile

Die & Mould

Oil & Gas

Agri & Earth Movers

Pump & Valve

Foundry

JH 500

The JH 500 Heavy Duty Horizontal Machining Center is designed for demanding applications, offering a stroke of 800 mm x 800 mm x 800 mm, a pallet size of 500 mm x 630 mm.

JH 550

The JH 550 Heavy Duty Horizontal Machining Center is designed for demanding applications, offering a stroke of 800 mm x 800 mm x 850 mm, a pallet size of 500 mm x 630 mm.

Applications Across Indian Industries

- Automotive Industry : Production of engine components such as cylinder blocks, crankcases, and transmission housings. Manufacturing of suspension components and other critical parts requiring high precision.

- Aerospace Industry : Machining of complex and lightweight components such as airframe structures, turbine blades, and landing gear components. Machining of alloys and composites.

- Heavy Equipment Manufacturing : Production of large, heavy components like gearboxes, hydraulic parts, and construction machinery components.

- General Engineering : Fabrication of tools, moulds, and dies for industries like plastics, rubber, and metal stamping.

- Energy Sector : Machining of components for wind turbines, and power plants.

Why JH Series?

Key Features that set HMCs apart

- Horizontal Spindle Layout : Gravity-assisted chip flow ensures cleaner operations and better finishes.

- Automatic Pallet Changer : Enables loading and unloading during machining — maximizing uptime.

- High Structural Rigidity : Designed for heavy-duty operations with excellent vibration damping.

- Multi-Axis Capability : Handles complex geometries with ease and flexibility.

- Better Tool & Workpiece Access : Facilitates intricate and deep-pocket machining.

Why Choose an HMC?

- Higher Productivity : Multiple operations in a single setup = faster turnaround.

- Superior Accuracy : Less repositioning leads to consistent precision.

- Seamless Automation : Automations like Pallet Changers and tool management systems reduce manual effort and errors.

- Efficient Chip Handling : Enhanced chip clearance reduces wear and downtime.

- Long-Term Cost Efficiency : Higher initial investment pays off through faster ROI and quality gains.