LMW Turnmill Series – Precision Meets Productivity

Delivering exceptional turning and milling capabilities in a single setup, the Turnmill Series from LMW combines high rigidity, precision engineering, and advanced tooling technology. Whether you need compact versatility or heavy-duty performance, our models are designed to meet diverse machining demands with unmatched efficiency.

Turnmill Centers

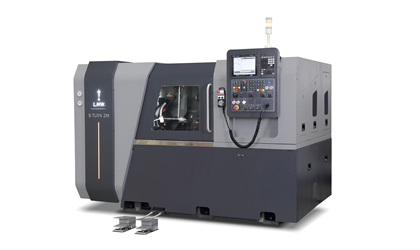

S Turn 2M

The S Turn 2M Turnmill Center is a versatile solution with a maximum turning length of 400 mm, a turning diameter of 320 mm, and 200 mm chuck size.

LR40TM L25

The LR40TM L25 Turnmill Center is built for large-scale operations, offering a maximum turning length of 2320 mm and a turning diameter of 550 mm. It is equipped with an A2-15 spindle nose, and 533 mm chuck size.

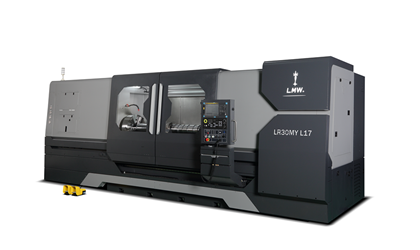

LR30MY L17

The LR30MY L17 Turnmill Center offers a maximum turning length of 1700 mm and a turning diameter of 520 mm, featuring an A2-15 spindle nose, and 533 mm chuck size.

Applications

Automobile

Pump & Valve

Aerospace

Electronics

Energy

General Engineering

Oil & Gas

Defence

Railway

Why Choose the LMW Turnmill Series?

- Multi-Operation Efficiency – Turn, mill, drill, and tap in one setup

- Reduced Cycle Time – Minimize handling, maximize productivity

- Precision Engineering – High rigidity structure for superior accuracy

- Operator-Friendly Interface – Intuitive controls for easy operation

Unlock faster production, greater accuracy, and reduced setups with the LMW Turnmill Series.

We also offer a wide range of other Turnmill Series models to cater to diverse component sizes, materials, and production needs.